On 19.03.2018 we received the order confirmation for a GRU 1060-2 mobile crane from Grumalu. The delivery time was given 4 to 7 months after placing the order.

On time on 19.03.2018 we have made the first payment according to the contract. The payment of further installments had been agreed as a function of production progress. Already on 09.05.2019 Grumalu requested the second of three payments. We thought it was a great idea, and that's fast. After all, after 6 weeks we had already paid 70% of the bill.

But then everything else went "a little slower". The aim was a delivery to our in-house fair in September 2018. Well, that was not quite done. Last but not least, when we checked the sent pictures and videos in April 2019, we realized that not even the locking sleeves had been installed in the built-in hydraulics, although the manufacturer (Leimbach) clearly described this as mandatory.

Since we had urgently required the installation of the locking sleeves before we could afford the last installment, Grumalu then forcedly installed the missing securing sleeves.

Subsequently, we have then received the agreed function videos of the truck to be delivered and made on the third installment on 17.04.2019. The 4 to 7 months had already become more than 1 year. On 6.05.2019 we finally got the mobile crane - the result was "very sobering".

Over the next few days, weeks, and probably months, we will accurately document the delivery status and required repairs. In doing so, we will consciously abstain from a valuation in order to ensure an objective presentation.

- The crane truck is delivered as described with 2 counterweights in the rear. We also ordered 2 additional weights. The crane was delivered without rear weights.

- The crane is delivered with 2 separate remote controls. One is for controlling the base vehicle and the other is for the crane body.

A description of which functions are used where and on which remote control is not included.

- Hub covers are mounted on the wheels of the two rear axles. The wheels of the two front axles are missing.

- The two filters for the hydraulic systems were simply included. The installation was omitted at Grumalu.

- On the right side, the wheel of the Second Axis was oily. On closer inspection, we discovered that it was hydraulic oil dripping down from the overlying vehicle body. We will see the cause later.

- The hydraulic functions in the vehicle, the extension of the outriggers, did not work at all. The cause was that the oil hoses on the control block were leaking. There is no more oil bubbling, only foam

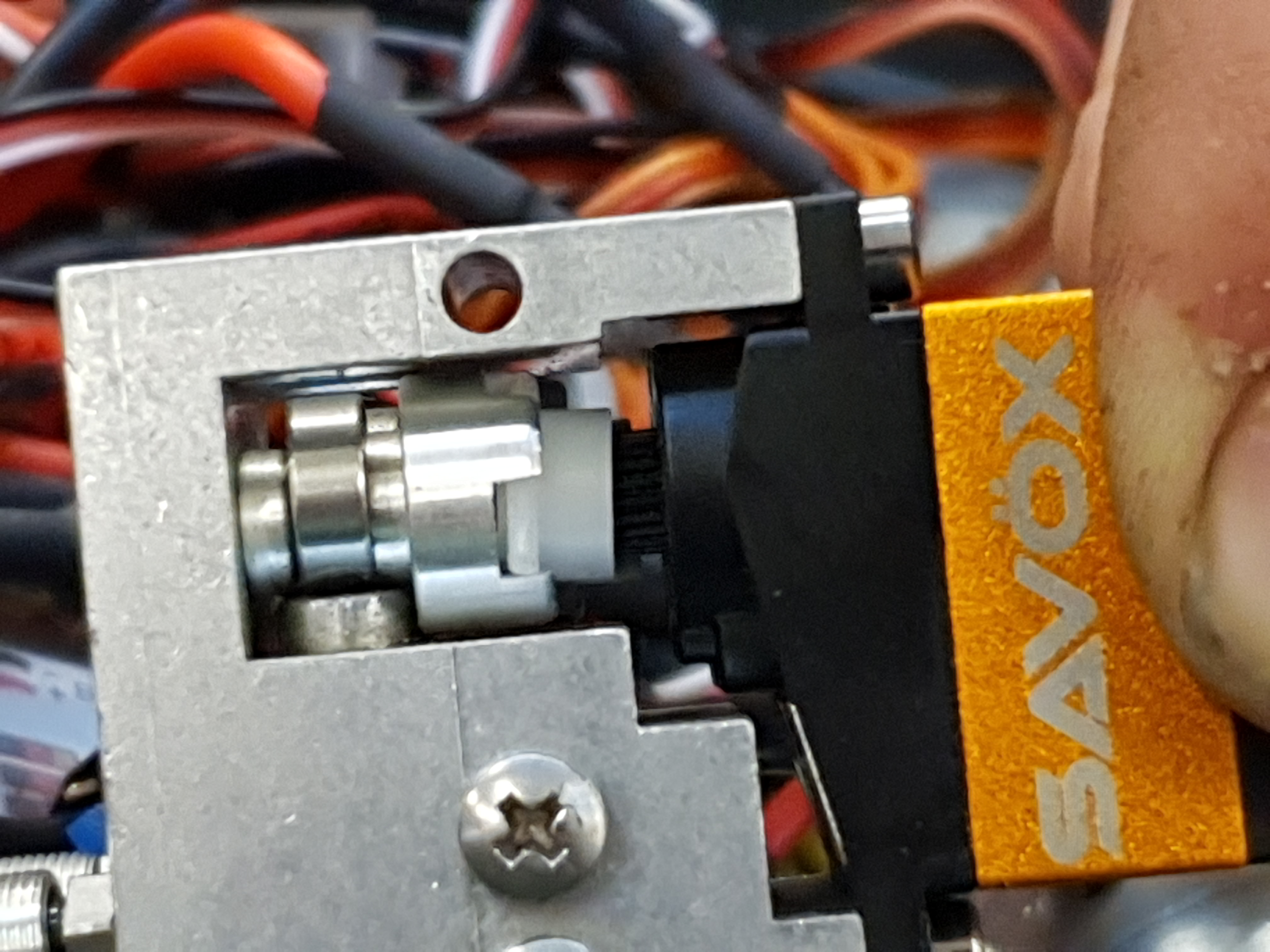

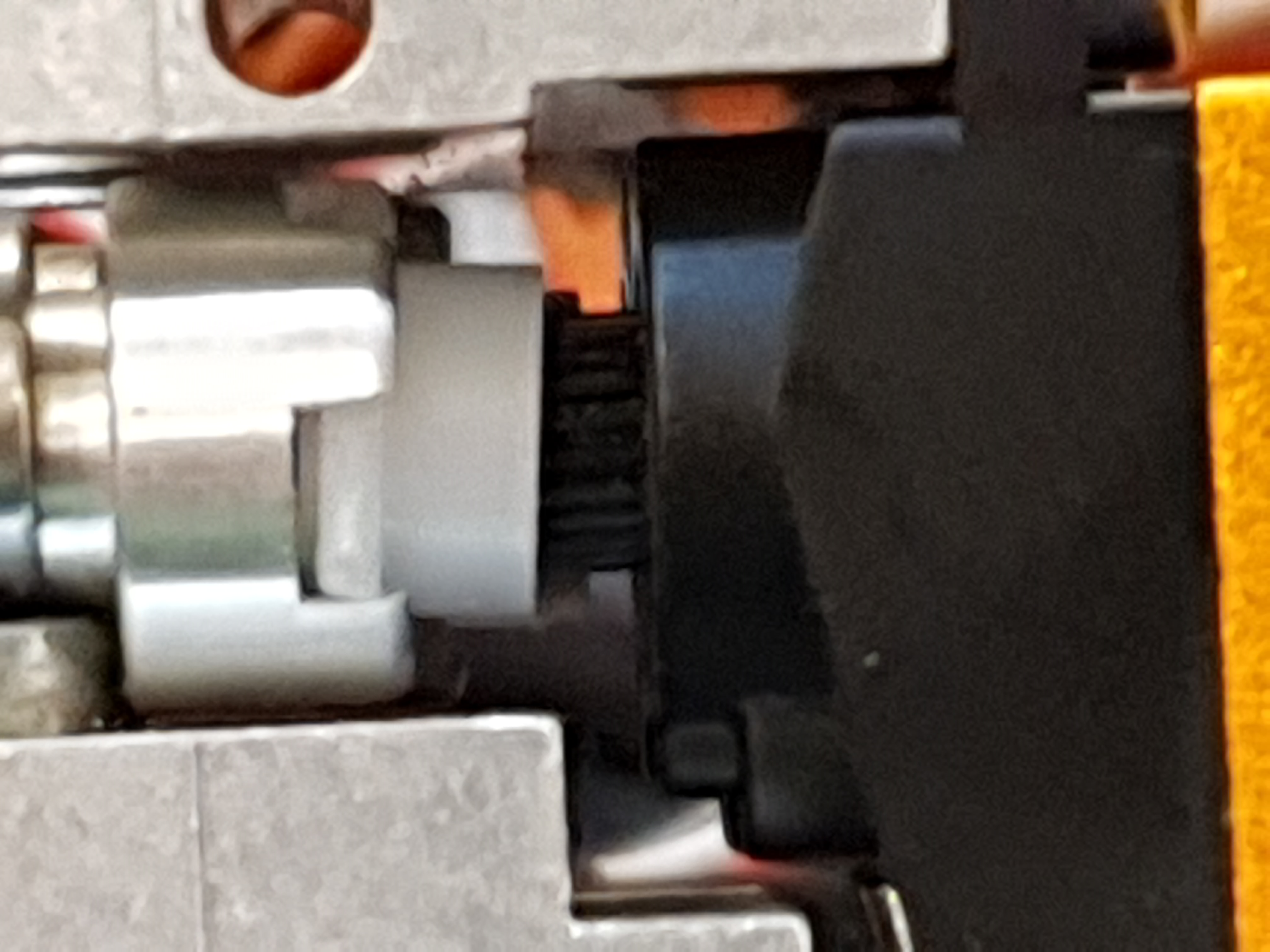

https://youtu.be/iEg2725qwXs - On the control blocks servos are mounted, which do not fit at all to the control blocks. Therefore, the servos do not fully engage in the servo horns. These servos have to be exchanged for matching servos.

- Use the rotary potentiometer on the left side of the transmitter to operate the rear supports. Only the servo moves on the control block, but the hydraulic pump does not start. Here is obviously not the programming of the mixer.

Use the rotary potentiometer on the right side to operate the front supports. There, the servo of the associated control block is activated and the pump starts up - but without oil in the system, this does not work. - On the one rear support the closure on the top has already fallen out.

According to photo documentation of the structure of the crane, the nuts used should be welded. Then they would certainly NOT have fallen out. - The flashing lights will light up immediately when the battery is connected. Switching on and off via the remote control is not provided.

- The flashing function on the built-M24 are apparently wrong wired. If you blink on the left, the vehicle flashes in the front left and rear right. If you blink on the right, then the vehicle does not flash at the front right and rear.

- The transparent inserts of the taillights were not mounted and missing.

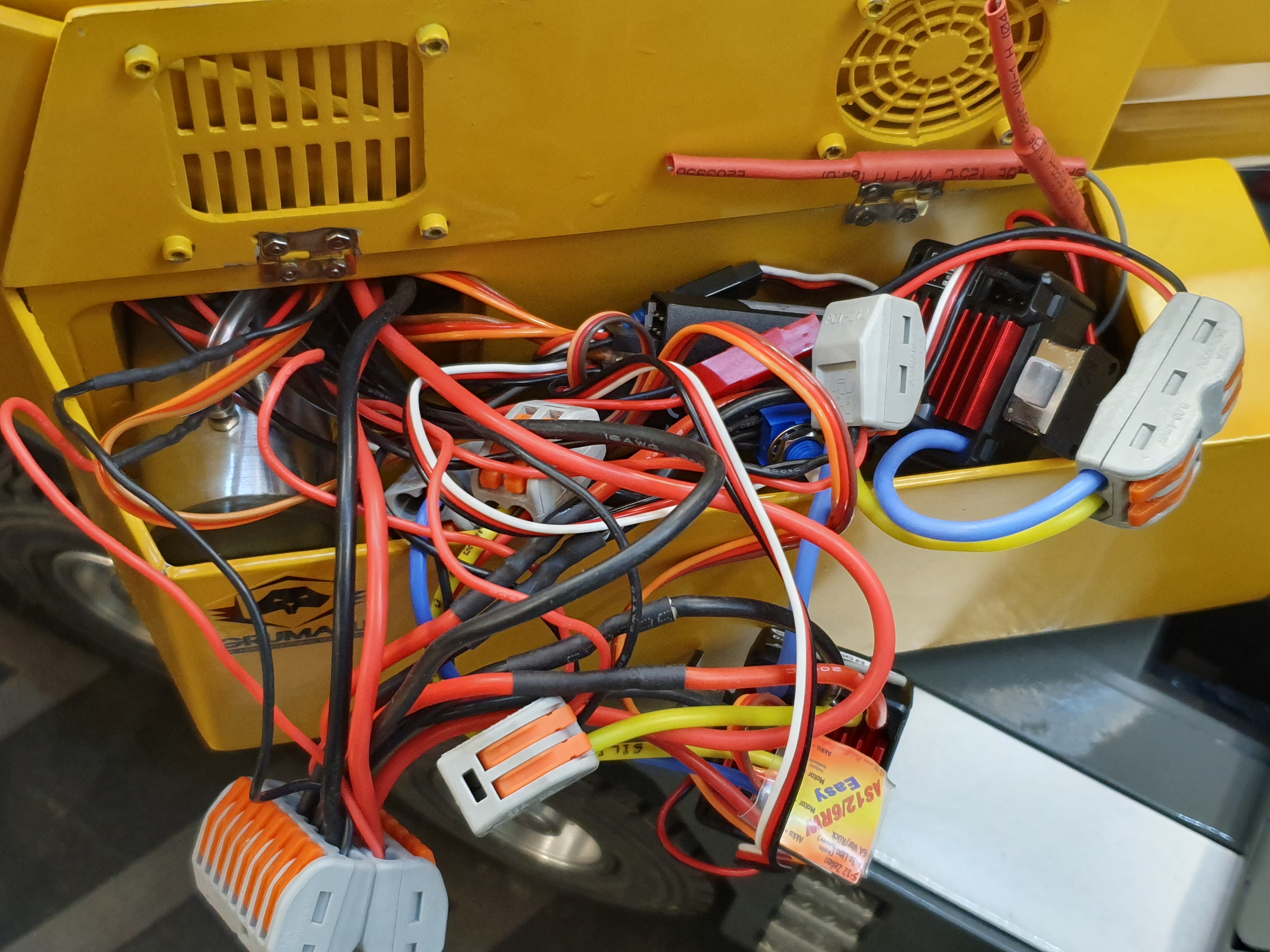

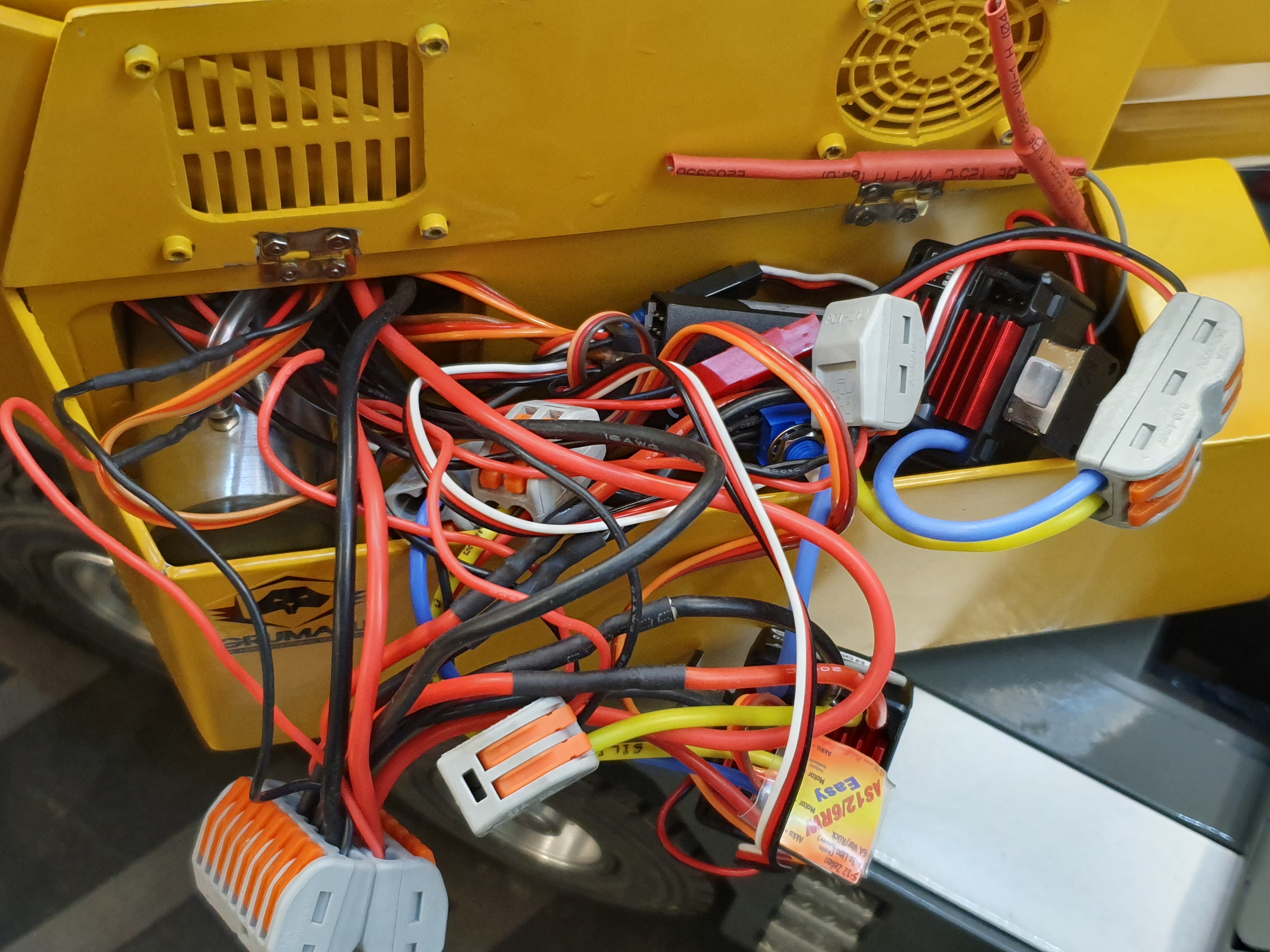

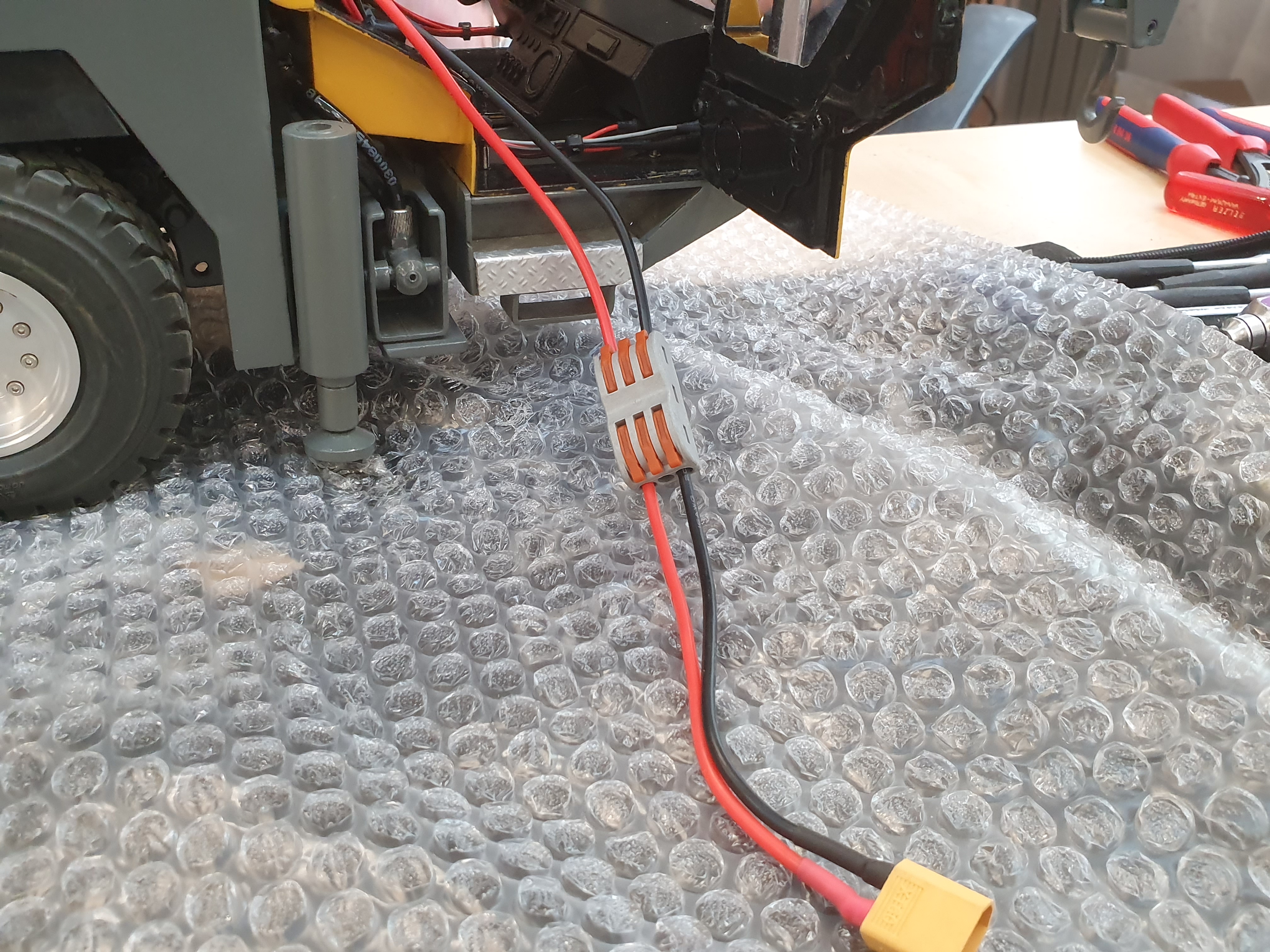

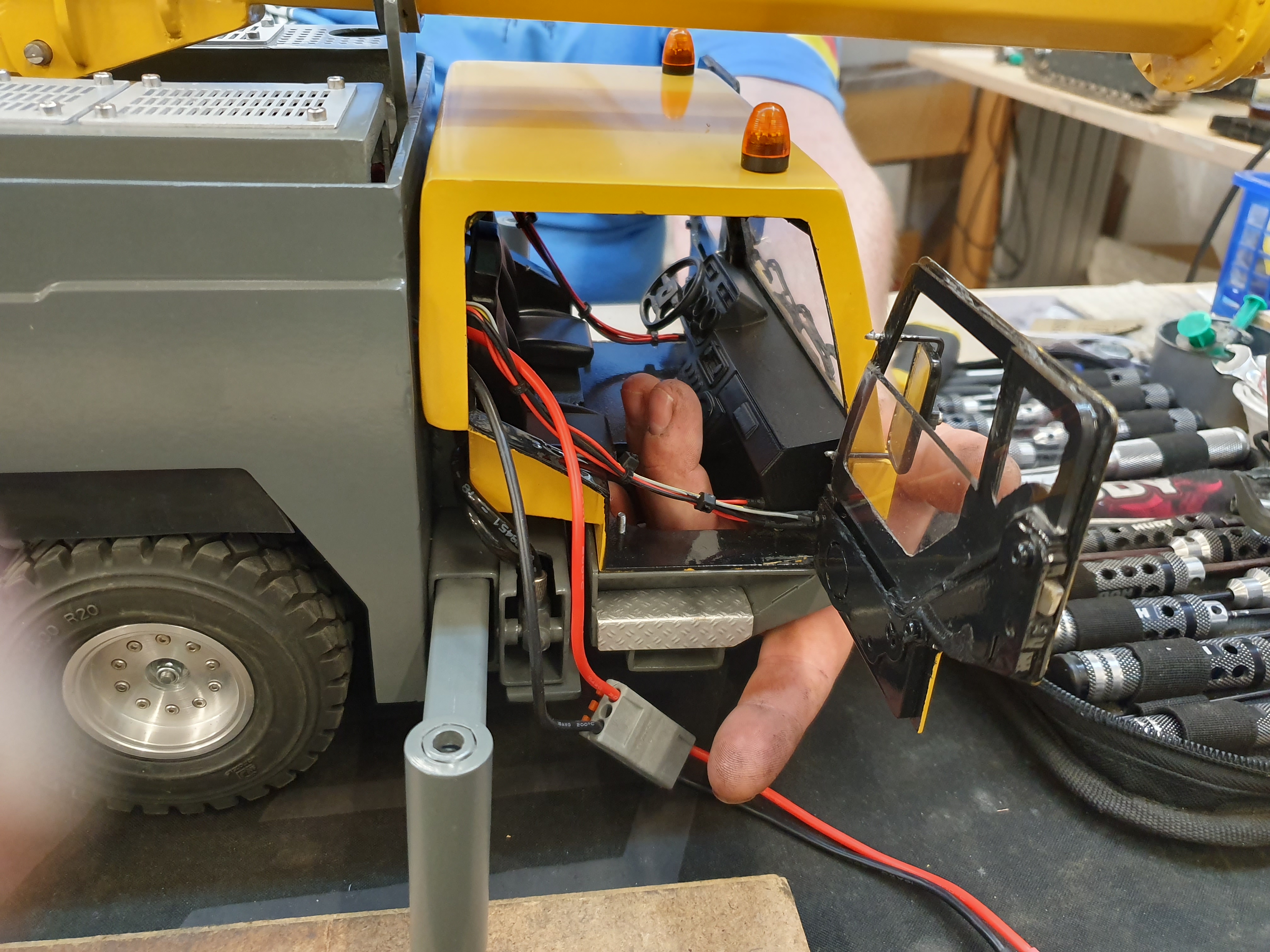

- The wiring and tubing has its own charm.

- The vehicle was ordered and delivered with an interior of the driver's cabin for a surcharge. However, it is planned to position the drive battery in the cab. At this point, the optics suffers a bit.

What should be the big hole in the floor of the cab, is not so easy to see.

- Now we turn to the crane body. Sound and horn work, but are operated via a rotary pot. This is something you control usefully with a button.

- Turning the crane does not work at all. The reason for this is that the pinion does not touch the main sprocket.

https://youtu.be/OGYuyQoL1yk - The rolling in and out of the rope works.

- The lifting of the crane arm unfortunately did not work either. You hear the hydraulic pump start up, but the cylinder does not go out. Again, the cause of the error was quite simple: The lid of the hydraulic pump had chipped and all the oil leaked.

Transport damage was said by Grumalu. Only we ask ourselves, then who had stuffed the paper around the tank to absorb daa oil? - Last but not least we wanted to test the extension of the arm. He moved only a few millimeters and then it cracked. After that, it did not move anymore, only the engine was running. The cause was that the clutch to the drive motor was broken.

All in all, the vehicle is anything but functional and that although we have made the final payment only after we had "proven" the functionality of videos.

Anyway, the truck crane we've received here can not have been the one we were sent the videos from!

In the meantime, we have tried several times to reach an amicable agreement with Grumalu, but unfortunately all these attempts have been unsuccessful. To the missing parts, which we demonstrably ordered and paid, we have received no additional delivery.

Grumalu does not seem to think that any repair or any kind of compensation would be required for a function model in this delivered condition.

So we'll be compelled to file criminal charges for fraud against Grumalu. This lawsuit is directed against owner Marcos Miranda Reyes and also against Carlos Macia Caballero, who handled all communication and correspondence for Grumalu.

In the meantime, we assume that there will be no rework from Grumalu. Normally you would send a model back to the supplier in this condition and have it reworked or reclaim your money. But we regrettably found out from one of the leading credit bureaus, that Grumlau has insufficient credit. From the credit bureau we were advised against any business relationship with Grumalu expressly.

For that reason, we have to start with the problem of repairing the existing damage ourselves and supplementing and rebuilding the missing parts with our own resources. Thus, it is ensured for our customer that he - as ordered - receives a properly functioning mobile crane.

We will continue to report in detail below about these required work.