A description of the delivered status you find here:

01.07.2019

As expected, we did not receive a replacement from Grumalu and no subsequent deliveries. Therefore, we have begun to correct the damage and errors piece by piece:

First, we disassembled the crane body to access the individual components.

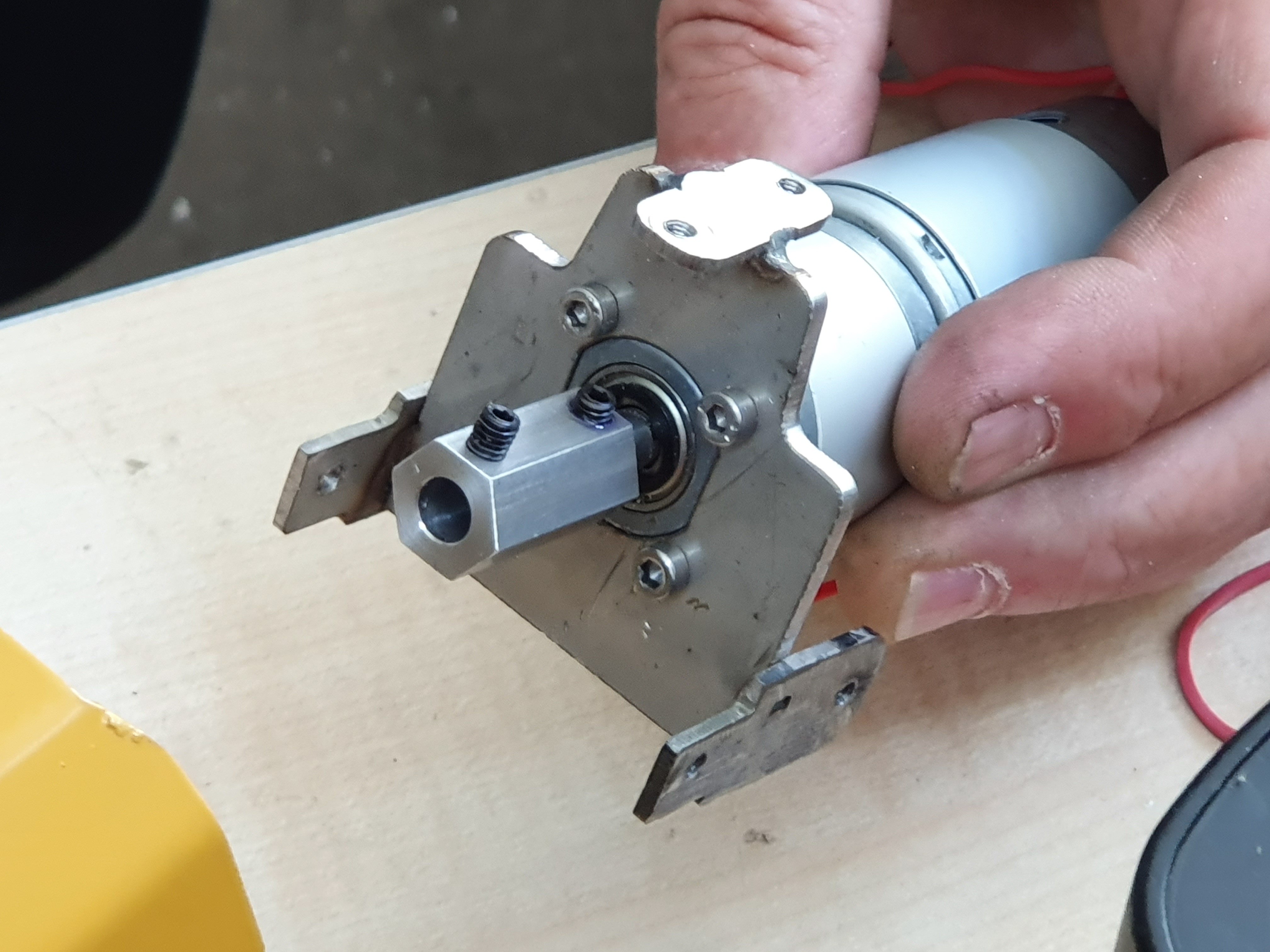

The coupling for the extension of the crane arm had been broken, because it was mounted too close to the extension spindle and therefore had seized up.

We have built and assembled a new clutch. On that occasion, all the screws that were loose had been tightened.

Now the extension works like expected.

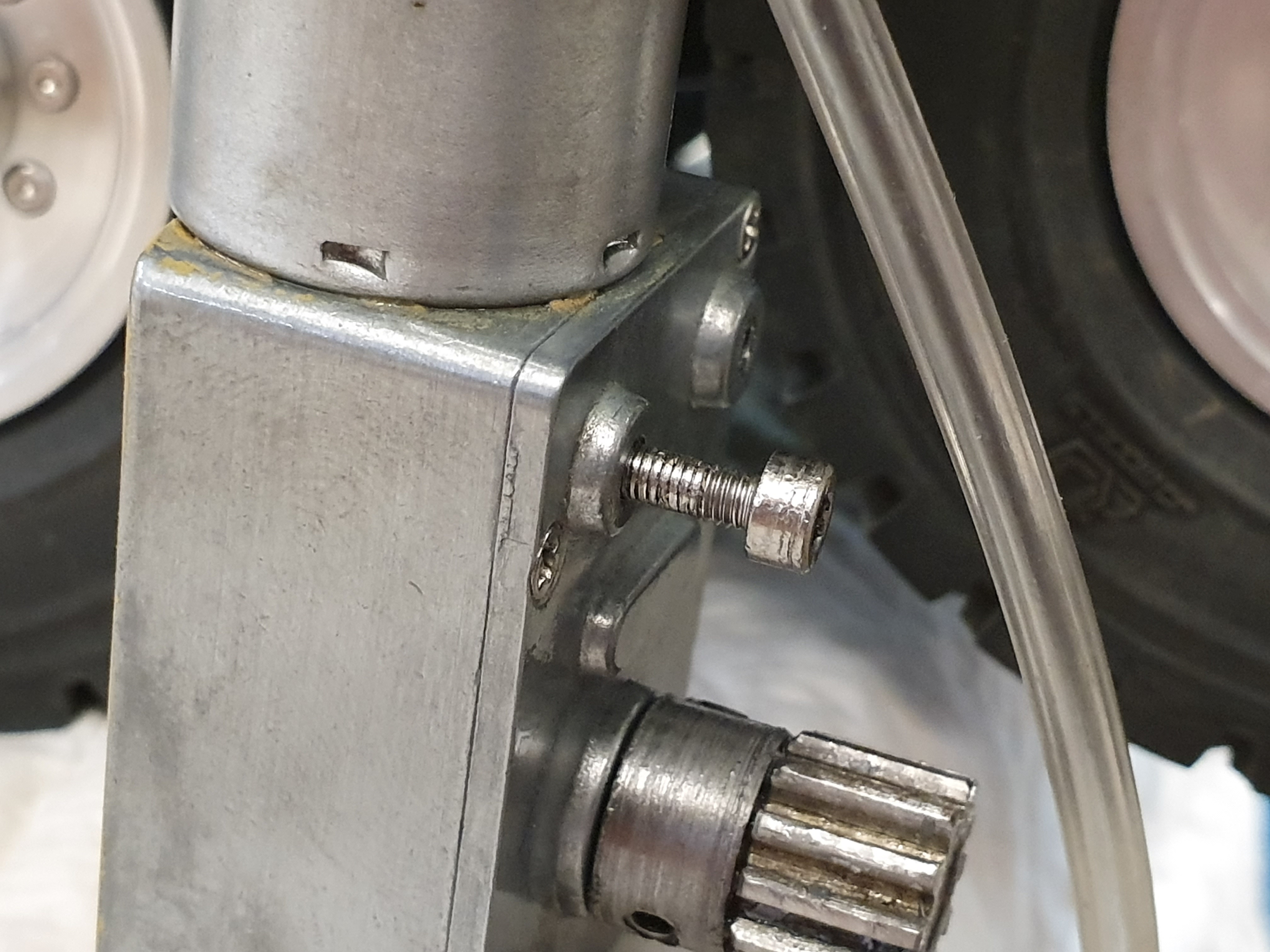

The next step was the rotary drive of the crane. According to Grumalu, the distance of the pinion had only to be "adjusted". That wasn't true.

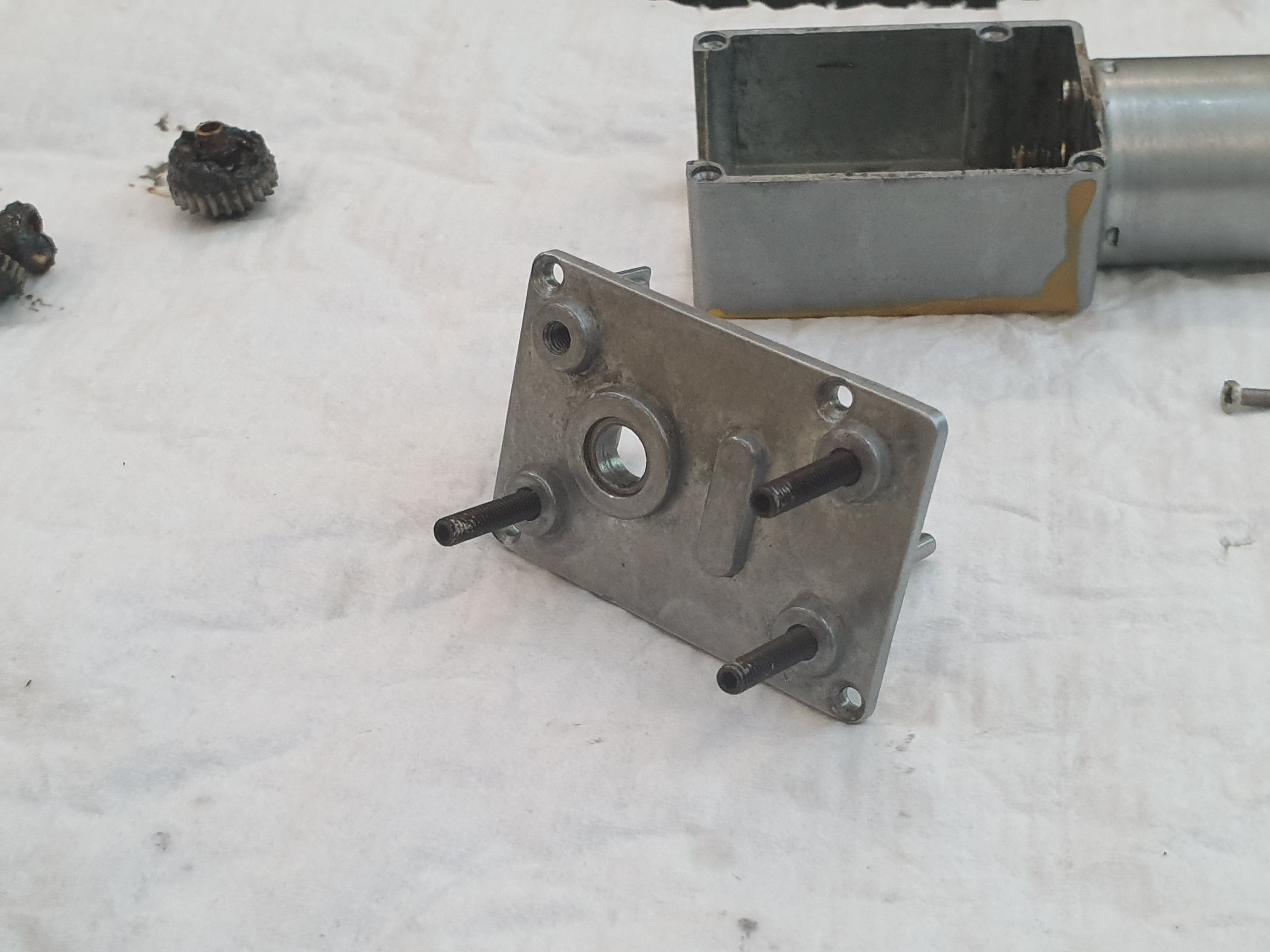

The inserted angle drive had been fastened with screws that were much too long. Therefore, the screws had unfortunately torn the threads out of the blind holes.

We have therefore restored the threads and used stud bolts.

05.07.2019

Then we dealt with the lifting of the crane arm.

It was noticeable that the crane had been delivered with a cracked tank cap.

We then filled the hydraulics as a test, deaerated and refilled until the crane boom was fully extended upwards. Then came what had to come, when shutting down the crane arm, the lid burst out of the tank, because the tank could not absorb the required oil volume for the cylinder. Although it is a double acting cylinder, the volume of the two chambers is very different.

It was also clear why the truck crane had been delivered with a cracked lid. Obviously, Grumalu had the same problem and then simply delivered the crane without fixing the problem. A professional solution is this certainly not!

We then tested the cylinder volume and found out that the lifting chamber of the cylinder contains 50ml of hydraulic oil. In the chosen design, the tank would be too long and would not fit into the model. So we will also adapt the hydraulic pump and the tank to the conditions.

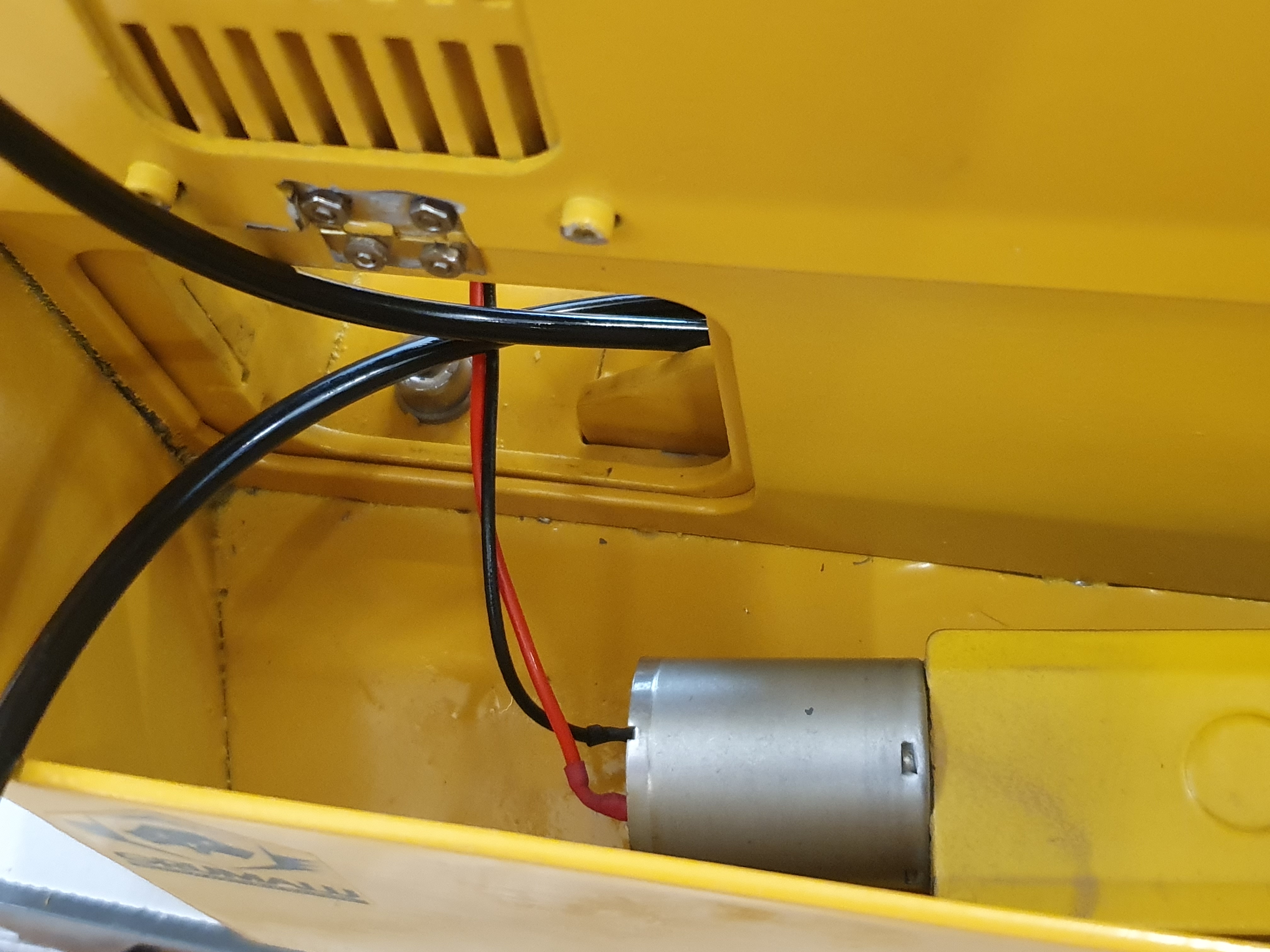

That's why we have removed all electronic and hydraulic components.

Now we have redesigned the distribution of the components in the superstructure. On the one hand, the hydraulic pump and the entire electronics are housed. In the free middle part and in one part of the compartment on the opposite side, a tank is built so that it fits exactly into the existing geometry of the upper carriage. This leaves sufficient space in the elongated compartment for the control valve and the battery, which was previously stored visible in the crane cab. We will then design and produce a facility for the crane cab.

We have also designed the counter weights and now have them lasered from stainless steel. Hoping that Grumalu still fulfills the delivery obligation and supplies the ordered and paid weights, we do not want more.

To be continued!