01.07.2019

The work continues to progress.

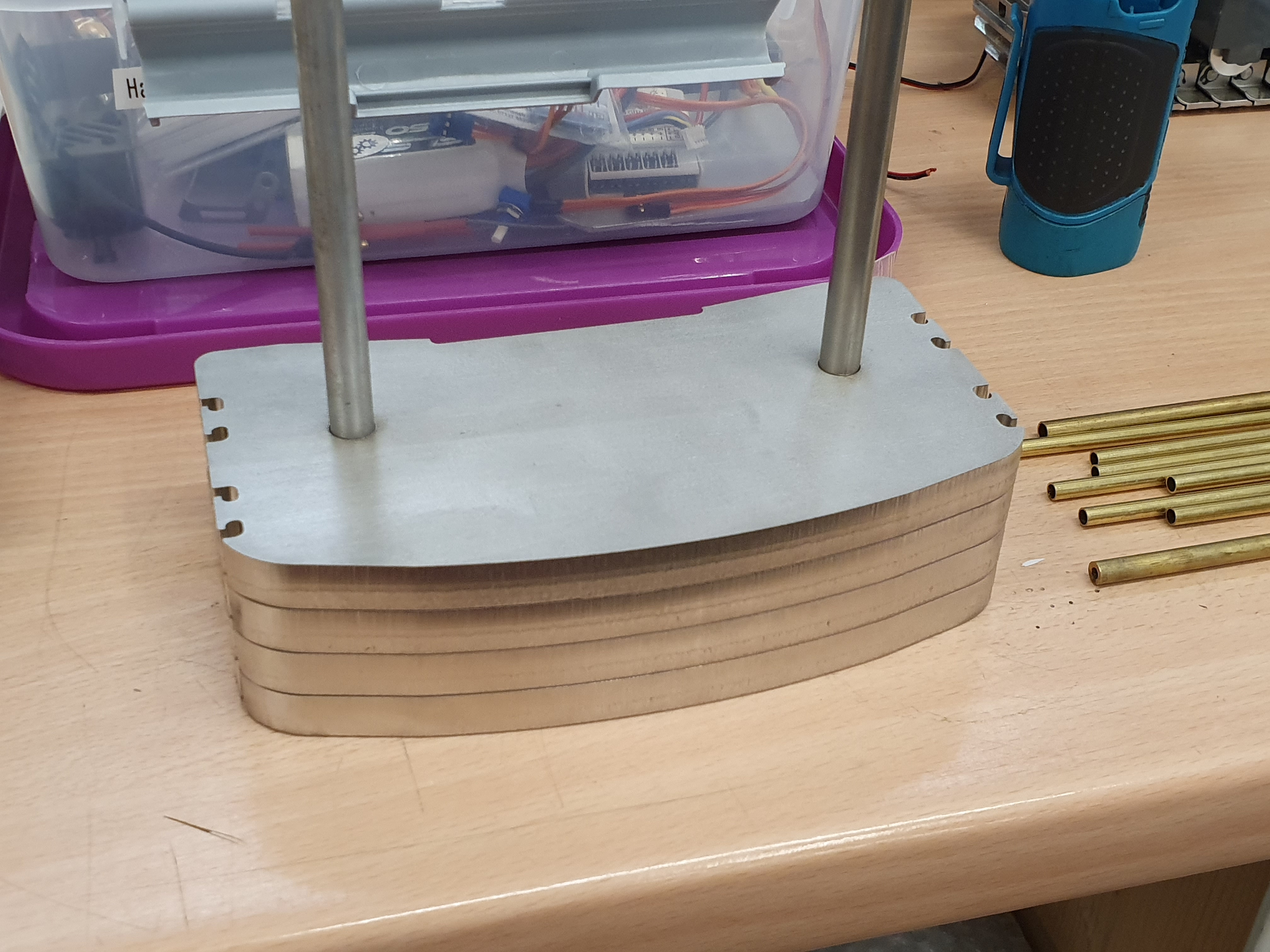

The counter weights we have drawn to match the shots on the vehicle and lasers made of 12mm stainless steel.

We also already revised the support. The nut in the upper end of the supports are now secured against being pushed out.

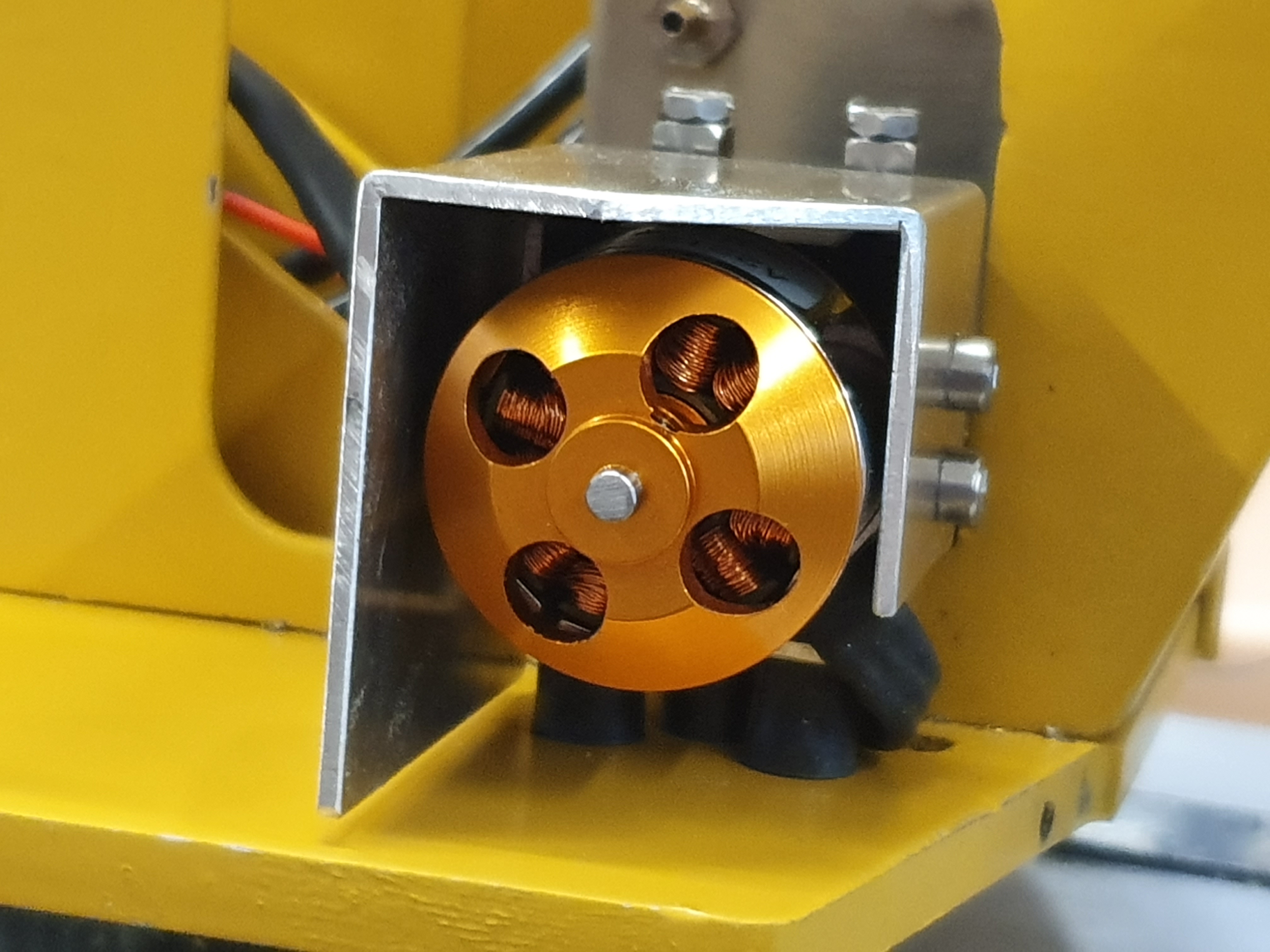

After that we did the hydraulics of the superstructure. The hydraulic tank used by Grumalu had a much too small volume and was therefore burst during retraction of the lifting cylinder.

We have designed a new hydraulic tank that fits exactly in the available space. This tank we made of stainless steel and additionally replaced the hydraulic pump.

Now the lifting operation of the crane works flawlessly:

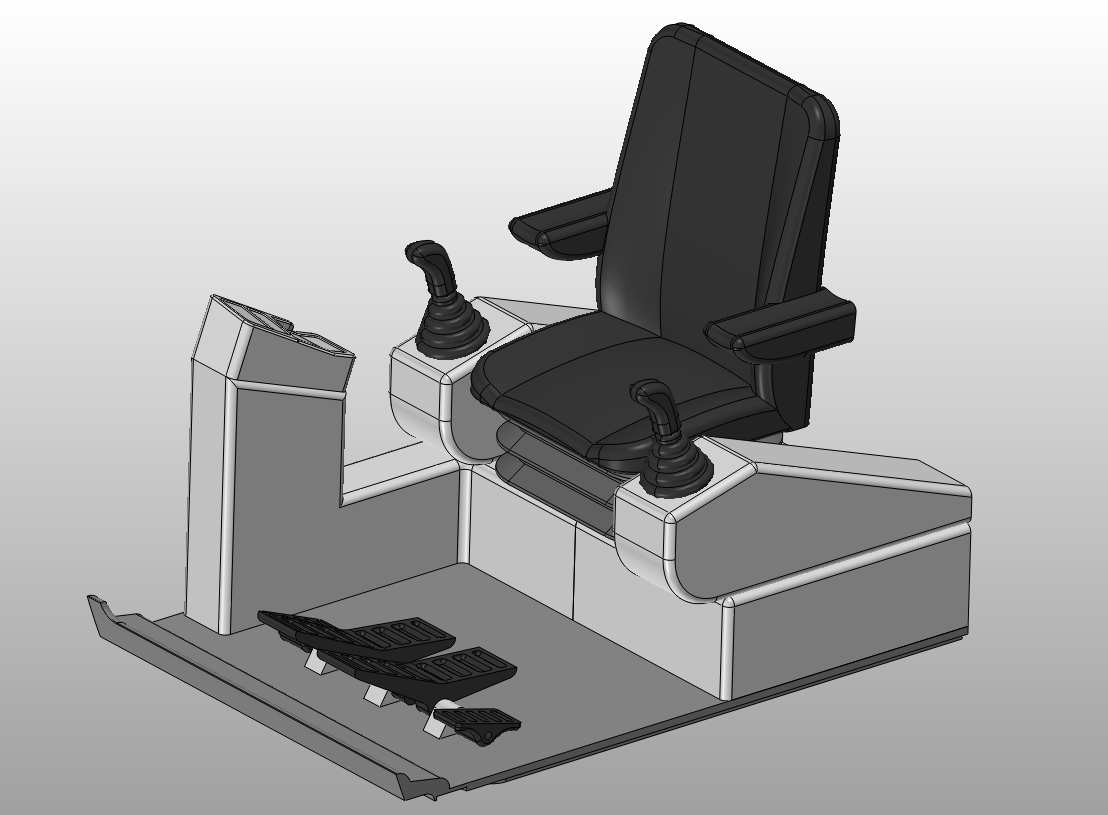

Something is also happening in the crane cab, the interior is already constructed and 3D printed.

We have created a little space under the seat, so that we can hide the sound module in the cabin under the seat.

To be continued!